Heat recovery is an often overlooked technology that greatly benefits businesses and the environment. By harnessing the power of heat recovery, companies can unlock hidden value in their processes and reduce energy costs. Heat Recovery technology can also improve the environmental performance of businesses by reducing their carbon footprint and decreasing their reliance on fossil fuels. In this blog post, we’ll discuss the potential of heat recovery and how it can maximise efficiency and cut costs.

What is an Air Recovery Ventilation System?

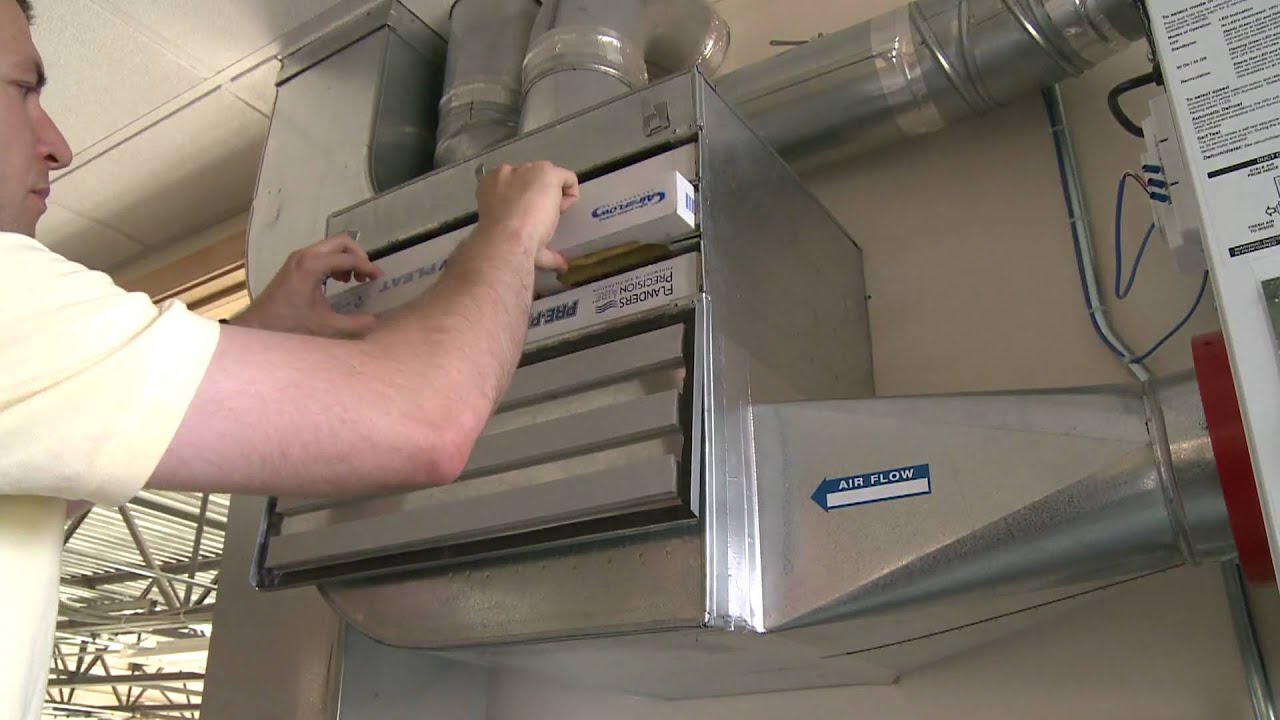

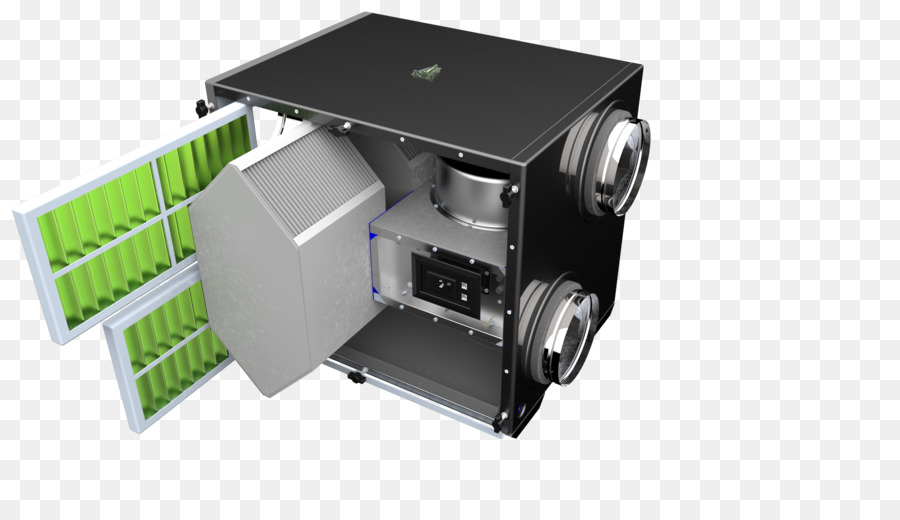

An air recovery ventilators system, also known as an air recovery unit or heat recovery ventilation system (HRV), is a technology that helps improve indoor air quality while maximising energy efficiency. This innovative system works by extracting stale air inside a building and replacing it with fresh air from outside.

But what sets an Air Recovery Ventilation System apart is its ability to recover and reuse the heat from the extracted stale air to preheat the incoming fresh air. It means that the system doesn’t waste energy already used to heat the indoor air. Instead, it captures the heat and transfers it to the incoming air, ensuring less energy is required to bring it to a comfortable temperature.

Not only does this help reduce energy consumption and lower heating costs, but it also provides a constant supply of fresh air, improving indoor air quality. By reducing the reliance on traditional heating methods, such as furnaces or boilers, an air recovery ventilators system can contribute to a more sustainable and eco-friendly building.

How Heat Recovery Unit Can Reduce Energy Consumption?

One of the main advantages of using a heat recovery system unit is its ability to reduce energy consumption significantly. It is achieved by capturing and reusing waste heat from various processes, such as ventilation systems, boilers, and manufacturing processes.

By implementing a Heat Recovery Unit, businesses can reduce the energy needed to heat water or space by utilising the captured waste heat. It means less energy is required from traditional heating sources, resulting in lower energy consumption and cost savings.

Additionally, using a heat recovery system unit helps reduce reliance on fossil fuels. By utilising waste heat, businesses can decrease their carbon footprint and contribute to a more sustainable future. It is especially important in today’s climate crisis, where reducing greenhouse gas emissions is crucial.

Another benefit of reducing energy consumption through a heat recovery system unit is improved energy efficiency. By utilising waste heat, businesses can maximise the efficiency of their processes and equipment. It can increase productivity and decrease downtime, resulting in overall cost savings.

Hrv System Cost is Affordable

When considering implementing a heat recovery ventilation (HRV) system, one of the main concerns for businesses and homeowners is the cost. However, the good news is that HRV systems are quite affordable, especially when compared to the long-term savings they provide.

The initial investment for an Hrv System Cost may vary depending on factors such as the size of the building, the specific system chosen, and any additional features required. However, it is important to consider the long-term savings that can be achieved through reduced energy consumption and lower utility bills.

An HRV system can significantly decrease the energy needed to heat water or space by capturing and reusing waste heat. It means lower energy bills and overall cost savings in the long run. Additionally, HRV systems reduce reliance on traditional heating methods, which can further contribute to energy cost savings.

Furthermore, HRV systems are designed to be efficient and require minimal maintenance, which helps to keep operating costs low. They are also built to last, providing years of cost-effective operation.

The Potential of Waste-to-Energy Projects For the Air Recovery Unit

The Potential of Waste-to-Energy Projects For the Air Recovery Unit

Waste-to-energy projects have incredible potential for maximising the efficiency of an air recovery unit. These projects involve converting waste materials, such as organic waste or biomass, into energy sources like heat or electricity. By incorporating waste-to-energy projects into an Air Recovery Unit, businesses can reduce their environmental impact and generate additional energy for their operations.

One example of a waste-to-energy project is using biomass waste from agricultural or forestry processes. This waste can be processed and converted into biofuel, powering the air recovery unit or other energy-intensive processes. By repurposing waste materials, businesses can minimise their reliance on fossil fuels and reduce the overall carbon footprint of their operations.

Additionally, waste-to-energy projects can address waste management issues. Instead of disposing waste materials in landfills, these projects offer a more sustainable solution by repurposing them for energy generation. It not only helps reduce waste volume but also provides a renewable energy source.

Why You Need a Whole House Ventilation System

A Whole House Ventilation System is essential to any home for several important reasons. Firstly, it helps to improve indoor air quality by continuously removing stale air and replacing it with fresh air from outside. It ensures that you and your family breathe clean and healthy air, which is particularly important for individuals with respiratory conditions or allergies.

Additionally, a whole-house ventilation system helps to regulate humidity levels in your home. Excess moisture can lead to issues such as mould growth, which can be detrimental to your health and your home’s structural integrity. By constantly circulating fresh air, a ventilation system helps to control humidity levels and prevent these issues.

Another benefit of a whole-house ventilation system is its ability to reduce energy costs. By harnessing the power of heat recovery, these systems can capture and reuse waste heat from various sources in your home. It means that less energy is required to heat incoming air, resulting in significant energy savings over time.

Overcoming Common Barriers to Implementing Mechanical Heat Recovery

Implementing mechanical heat air recovery systems can benefit businesses and the environment. However, several common barriers may prevent companies from adopting this technology. Understanding and overcoming these barriers is crucial to fully harnessing the potential of Mechanical Heat Recovery.

One common barrier is the initial investment cost. While heat recovery systems can lead to significant long-term savings, the upfront cost may deter some businesses. However, it is important to consider the return on investment and the cost savings that can be achieved over time. By focusing on the long-term benefits, businesses can see that the initial cost outweighs the potential energy savings and improved efficiency.

Another barrier is the need for knowledge and understanding about mechanical air heat recovery. Many businesses may need to know about the technology or its potential benefits. Educating business owners and decision-makers about the advantages and opportunities of heat recovery is essential to overcoming this barrier. Providing information on case studies and success stories helps build confidence and encourage adoption.

The Importance of Efficiency of Air Recovery System

An Air Recovery System efficiency is crucial in maximising heat recovery technology’s benefits. An efficient system ensures that the captured waste heat is effectively utilised to preheat incoming fresh air, minimising the need for additional energy sources. It reduces energy consumption and lowers heating costs for businesses and homeowners.

A highly efficient air recovering system can significantly impact overall energy savings. By effectively capturing and reusing waste heat, businesses can reduce their reliance on fossil fuels and decrease their carbon footprint. It is especially important in today’s climate crisis, where every effort to reduce greenhouse gas emissions matters.

Moreover, an efficient air recovering system can increase productivity and decrease downtime. By maximising the efficiency of processes and equipment, businesses can save on operational costs and improve their bottom line. Additionally, a well-functioning system ensures constant fresh air, improving indoor air quality and creating a healthier and more comfortable environment for occupants.

FAQ’s

1. What is the payback period for a heat recovery system?

The payback period for a heat recovery system varies depending on factors such as the size of the system, the specific technology used, and the facility’s energy consumption. However, most heat recovery systems generally have a payback period of around 2 to 5 years.

2. Are government incentives or grants available for implementing heat recovery systems?

Yes, many governments and energy efficiency programs offer incentives and grants to encourage the adoption of heat recovery systems. These incentives can offset the initial cost of installation and make the technology even more affordable.

3. Can heat recovery systems be integrated into existing buildings?

Yes, heat recovery systems can be integrated into existing buildings. Retrofitting existing buildings with heat recovery technology is viable and can provide significant energy savings.

4. Do heat recovery systems require a lot of maintenance?

Heat recovery systems are designed to be low-maintenance. They are built to withstand the rigours of industrial and commercial applications and typically require minimal maintenance.

Conclusion

The blog post has explored the untapped potential of heat recovery technology and how it can significantly benefit businesses and the environment. They discussed the importance of air recovery ventilators systems in improving indoor air quality and energy efficiency. We also highlighted how heat recovery system units can reduce energy consumption and lower costs.